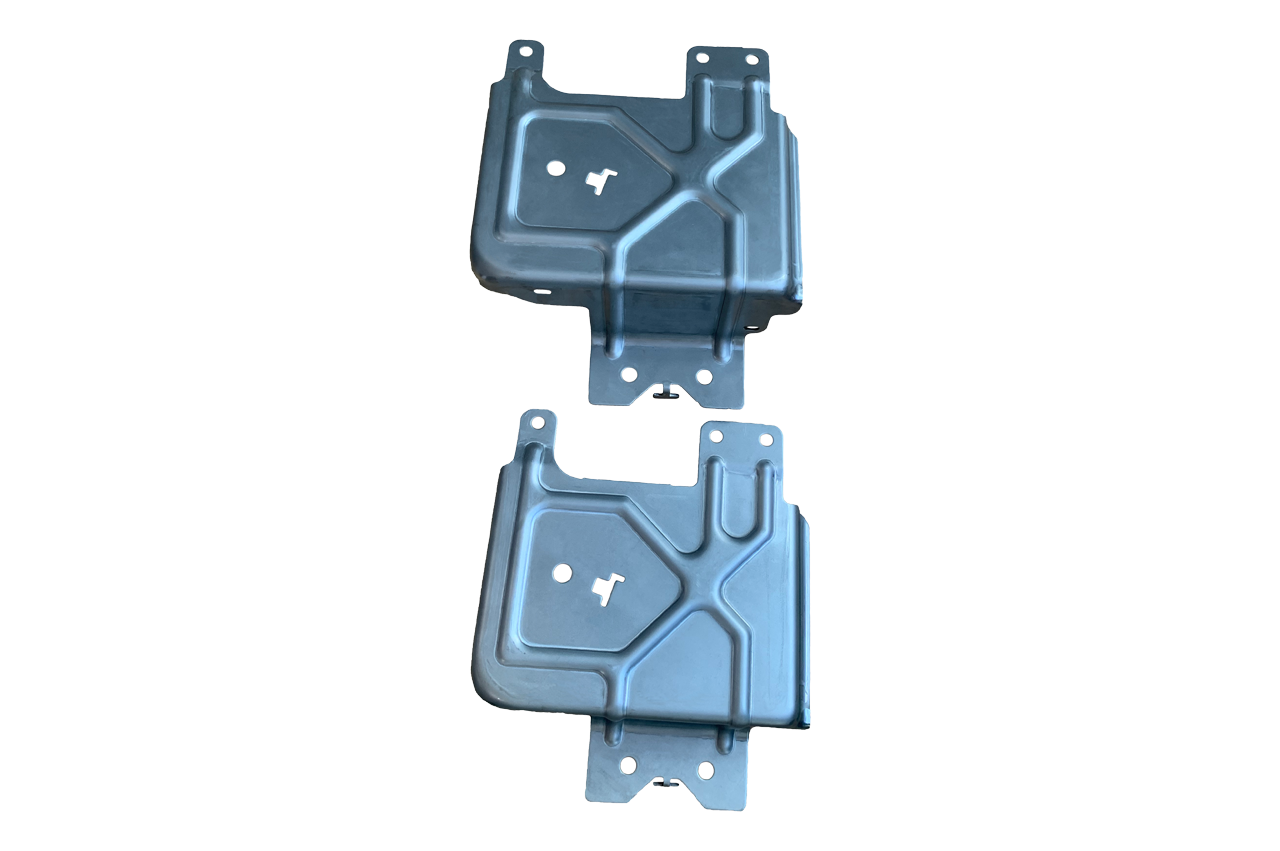

Reinforcement Assembly Bracket Window Head Lower Part

Part Name:

Reinforcement Assembly Bracket Window Head Lower

Material Grade: HSLA300+Z100

Material Size: 2.50mm x 742mm x 312mm

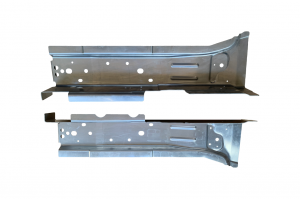

Stage Process: 800T Progression Tool

Cavity: two parts out

Complexity: Middle

Application: The part applicated to automotive reinforcement part

Press Machine: 1200T Mechanical, 2000T press

Inspection Tool: Checking fixture, Laser scan, CMM

Lead Time: 5 months

Technical Key Point: countermeasure to part fall away and wrinkle concern

Background:

Our customer concerned over part exit and fall away during doing process layout. Due to scrap shape the end area of the part will always interfere with the crop steel unless part falls forward / backwards first. This then will cause possible issues with part snagging and not clearing away quick enough and will reduce SPM of the tool. Due to this, our designers reviewed the part can be carried alternatively instead to allow for better fall away but also maintain access to CAM’s, which is why part is orientated currently how it is for CAM-Pi access.

At the last, part fall away from press smoothly and stable during part production.

Besides, there are wrinkle on corner shape of the part. Again understand adding pre-material shape during forming however our designers thought maybe cause some wrinkle and also high die wear on steels for this area with material scoring etc. They reviewed that having trim notch cut-out would improve. Finally in actual production, we found no wrinkle on corner shape of the part and the part have a good quality.

Our vision:

Wish all Meilin staff work happy and their families have a happy life and good health.

Our aim:

Become a first-rate moulding company in the word.

Meilin principle:

Devotes herself to creating a wonderful life for her employees, the maximum value for her clients, and permanent vitality for the enterprise.